Wire Harness Standards Print

Typically cable harness and wire harness services that manufacture products for automotive applications follow guidelines established by the society of automotive engineers sae or the u s.

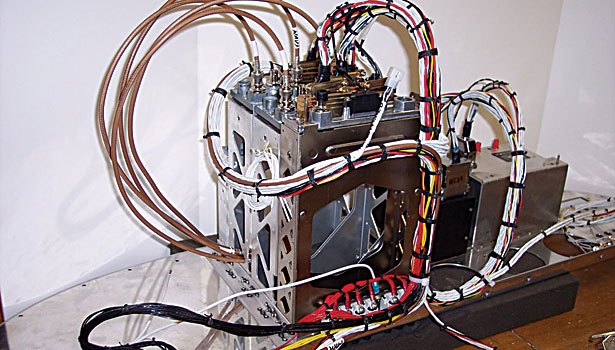

Wire harness standards print. 1 do we have to show all wires that are going from a connector. The use of right angle connectors shall be minimized and restricted to applications where stress free mounting of the cable assembly can be assured. Using a 3d cad system the wire paths are specified throughout the aircraft. Insulation chosen for the aircraft wire harness design engineer select wire part number to use.

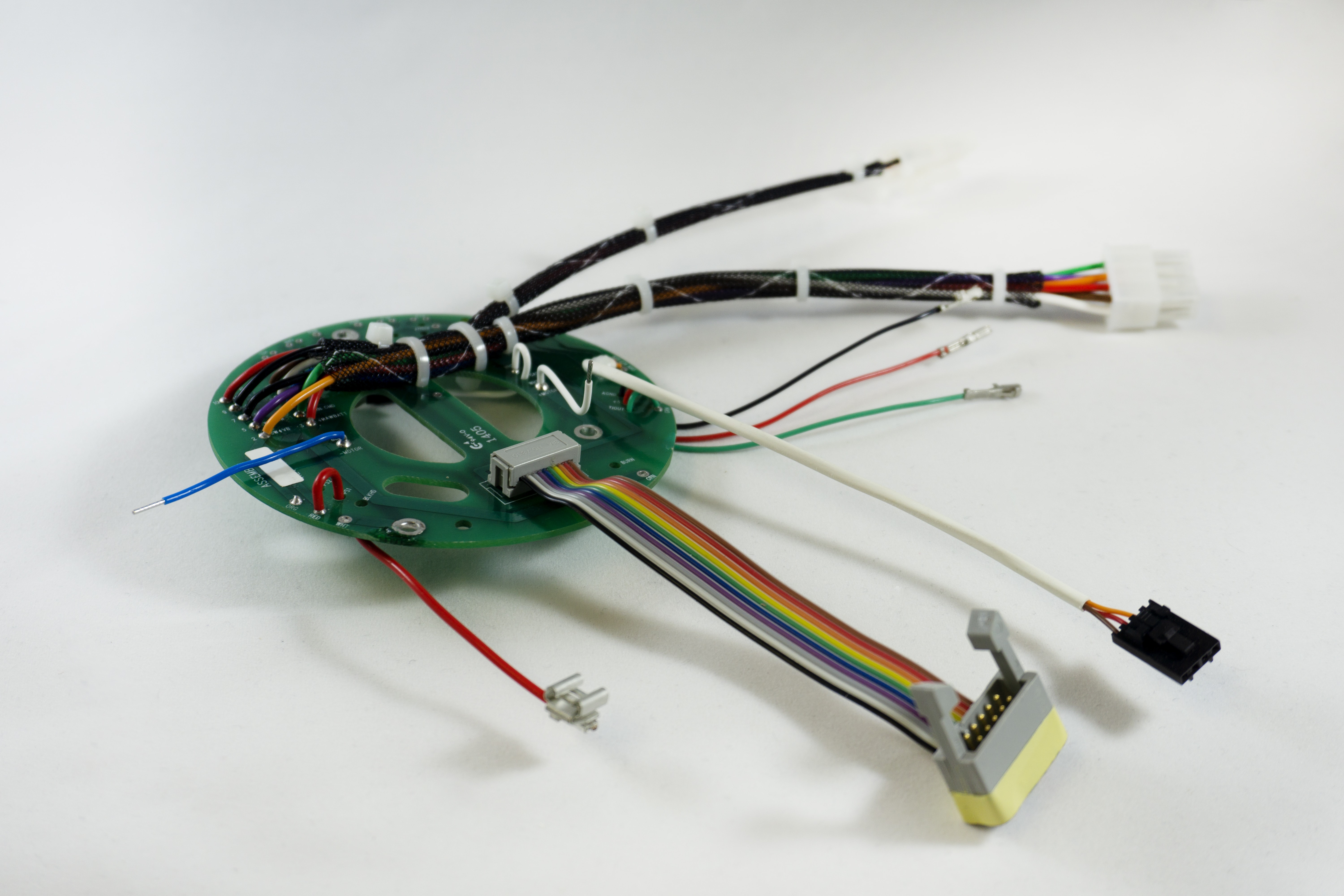

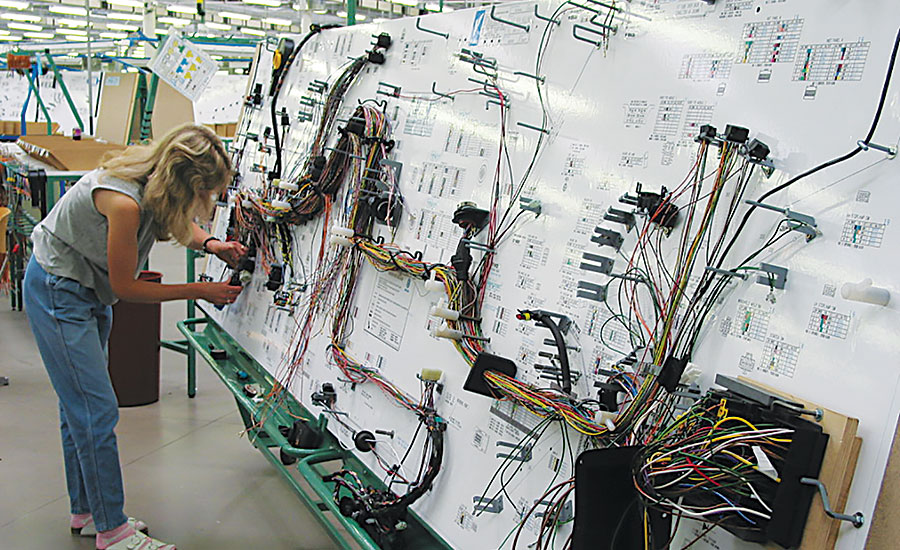

Cable and harness general requirements cont preferred. Hi all is there any asme standard for making wire harness drawing. As a result harness design and assembly were rarely automated the assembly time was long the quality was inconsistent and often much of the design work was done as the harness was manually assembled on the production line. Sometimes their wire harness design is completed and they know exactly what they need in a wire harness.

Doing so has allowed us to build a network of more than 2 000 ul certified wiring harness manufacturers based on end product investigations. Selecting cable harness and wire harness services requires an analysis of quality requirements. Posts tagged with electrical design standards for wiring harnesses paul johnston. Department of transportation dot.

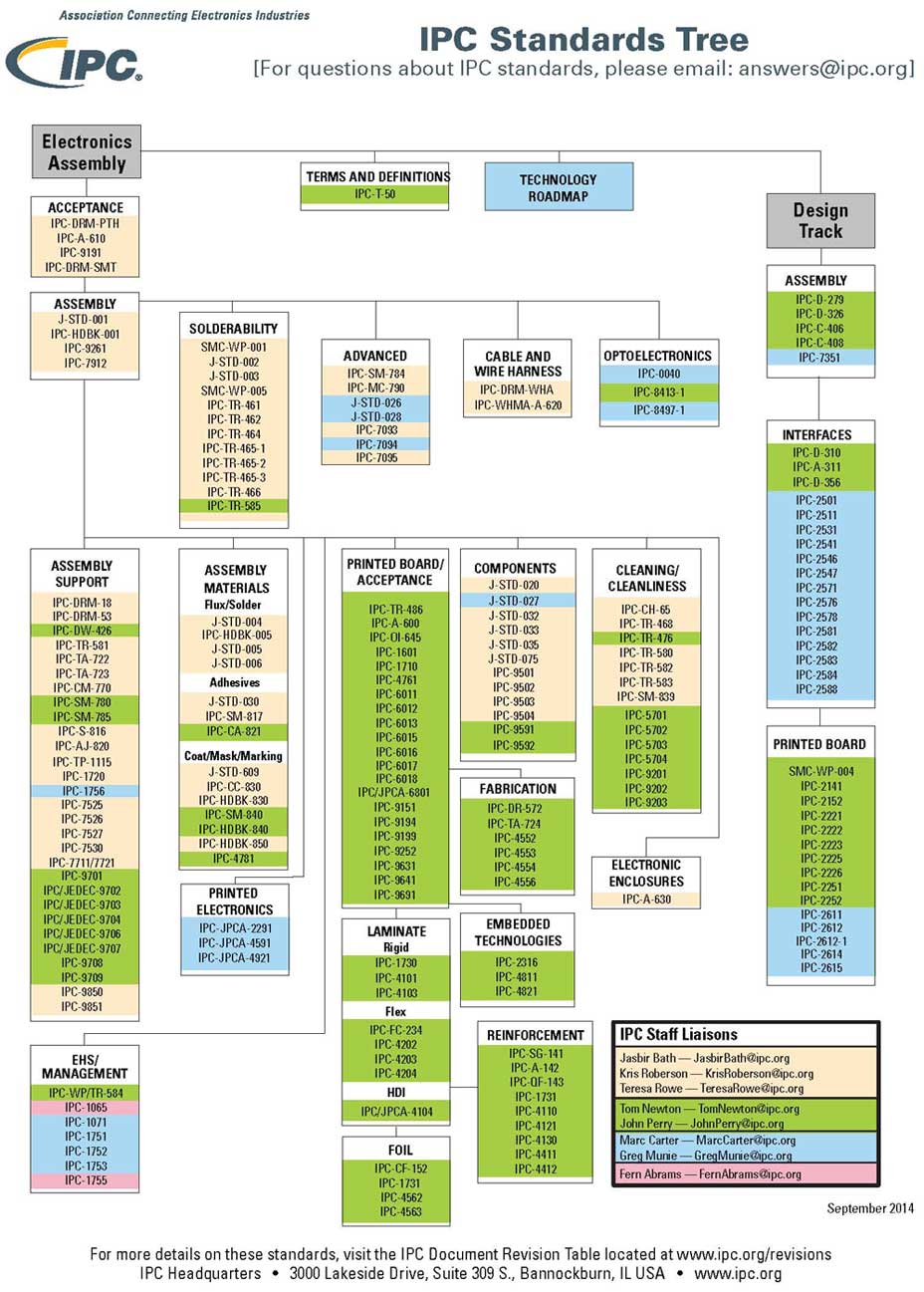

Build to print wiring harnesses. Many ipc standards are closely related to other ipc documents so it s important that they use the same approach to make it easier for those who use multiple documents to move from one to the next. Or just show one line and wire harness drawings standard drafting standards gd t tolerance analysis eng tips. In addition connector disconnects will determine when a wire goes through a bulkhead.

Standards wire harness automotive electrical and electronic systems design capital harness systems chs. In the past wire harness design was done on the fly during assembly. Each wire in a wire segment is then uniquely identified see chapter 4 wire. Electrical wire harness design blog.

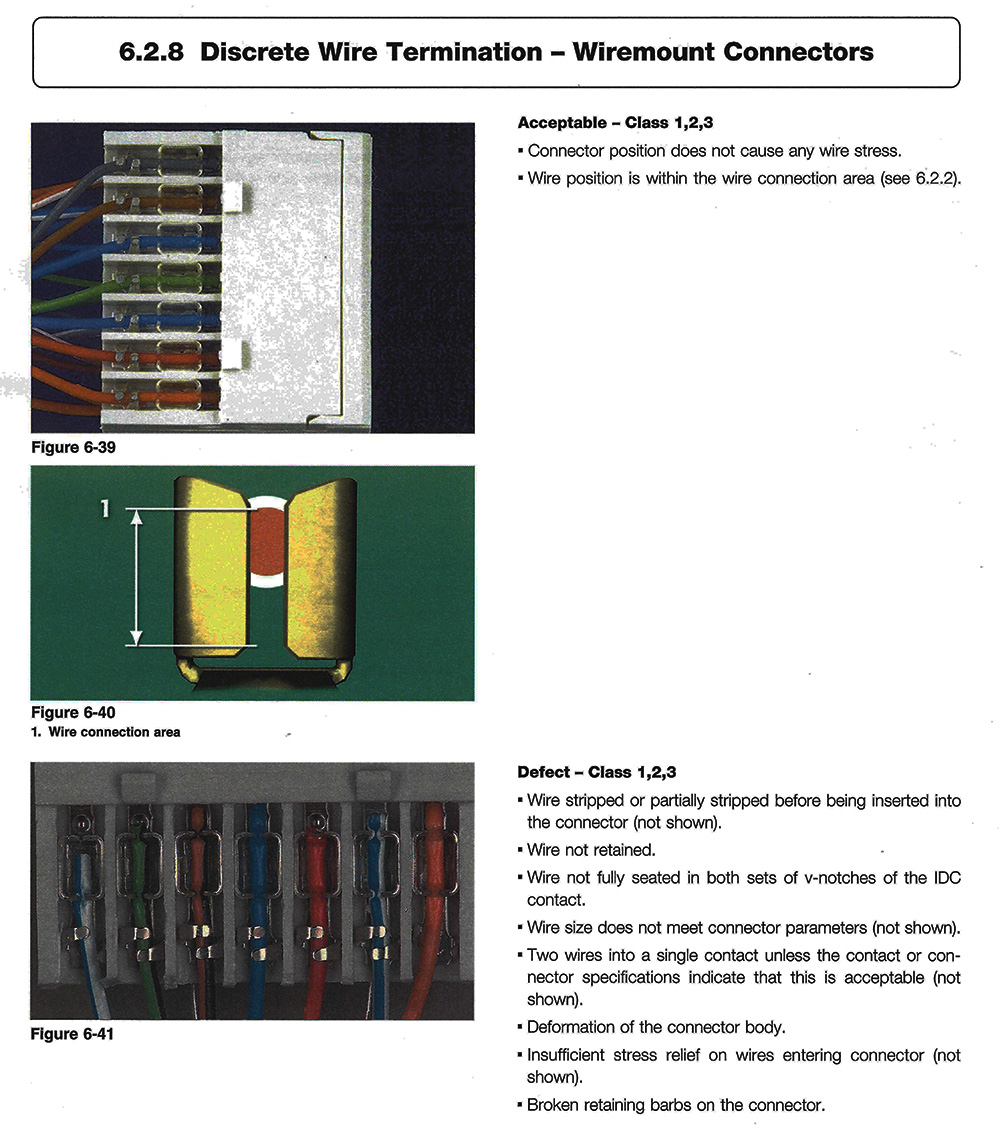

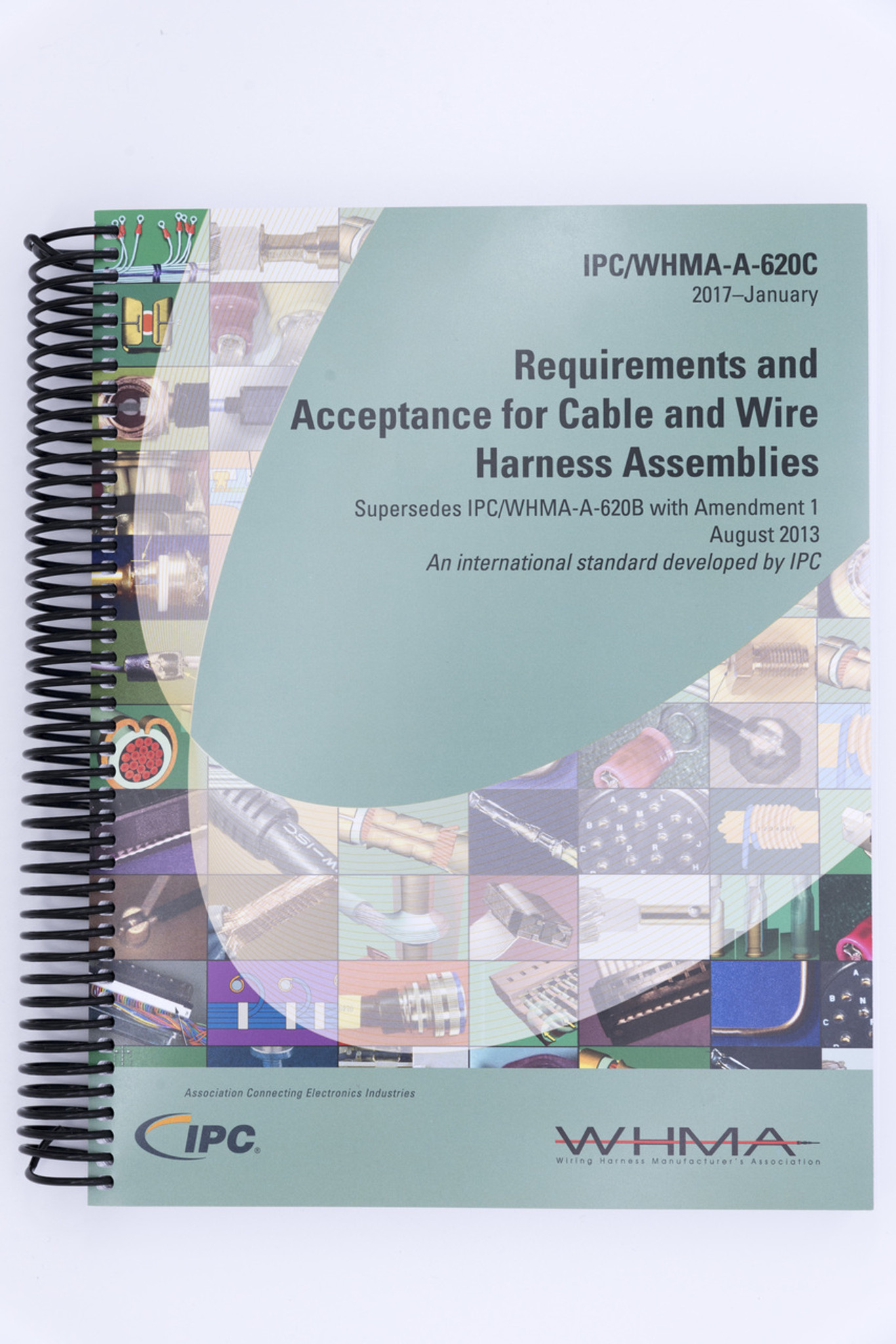

Ipc whma a 620d delivers improved performance and acceptance requirements for cable and wire harness assemblies. Their problem is the quality they receive from their current wire harness supplier is not up to par with their standards. Our wiring harness traceability program monitors cables as they move from the manufacturing plant to the harness producer and into the final assembly line.